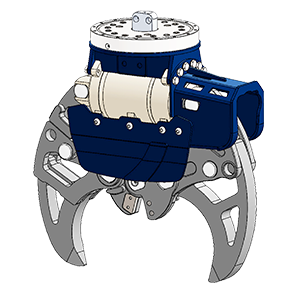

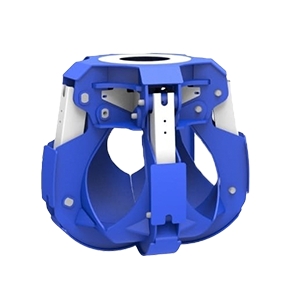

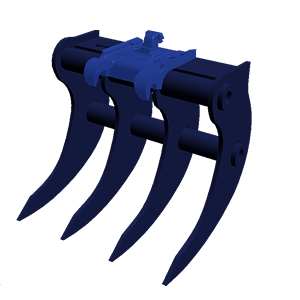

LOG SPLITTER CLAMP SPAK

The wood clamp

Splitting / cutting large logs with minimum effort is made easy !

Mainly used to harvest and process timber, they can also be used as handling grippers and as raking tools.

More information

- Easy transport of splitting equipment

- Gripper structure designed to reduce

the force needed for blade penetration - Manufactured using high-strength steel

- Over-sized cylinder

- Case-hardened, tempered bushings

LOG SPLITTER CLAMP SPAK

TECHNICAL FEATURES

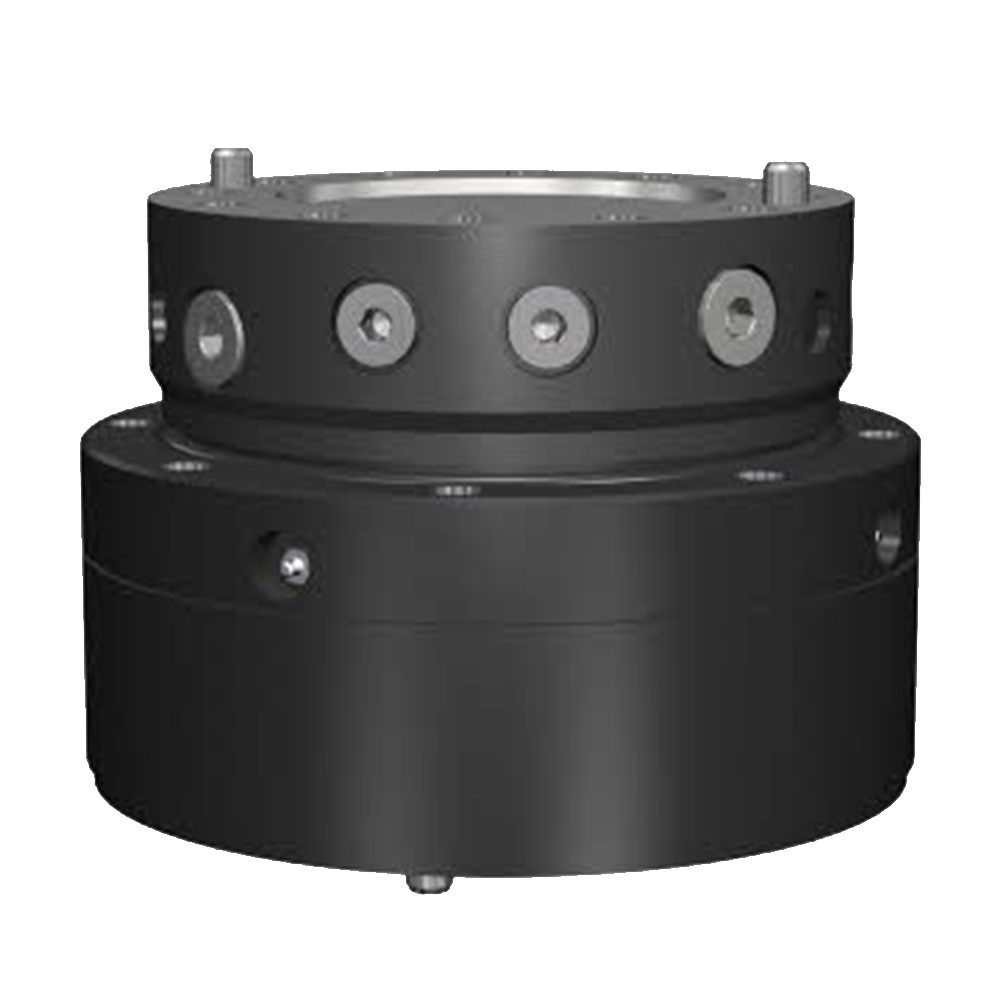

Focus ON

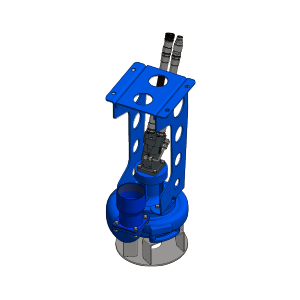

the rotor

We use compact, powerful rotors with higher rotation torque than standard pinion motors.

- The rotors with plain bearings are based on a new sealed transmission principle which protects the motor from external stress, increases its longevity and reduces maintenance.

THE RANGE SPAK splitter clamp

| Réf. | Weight without rotor (kg) | A max opening (mm) | D max width (mm) | Force on the blade (ton) | Oil flow rate (L/min) | Max pressure (bar) | |

|---|---|---|---|---|---|---|---|

| Model D / 1 2 – 3,5t | YSPRT040DB | 160 | 600 | 150 | 15 | 30/40 | 250 |

| Model E / 2 3 – 5t | YSPRT060EB | 160 | 600 | 150 | 15 | 30/40 | 250 |

| Model F / 3 6 – 9t | YSPRT080FB | 340 | 800 | 200 | 22 | 60/80 | 300 |

| Model G 9 – 12t | YSPRT100GB | 540 | 1 000 | 250 | 28 | 80/100 | 300 |

| Model H 12 – 17t | YSPRT120HB | 1 050 | 1 400 | 300 | 30 | 180/200 | 300 |

| Model I 17 – 24t | YSPRT170IB | 1 800 | 1 800 | 400 | 42 | 250/300 | 300 |

OUR EQUIPMENT IN PICTURES

Documents

Brochure UK

SAFETY QUESTION

In comparison to conical screw systems, the splitter clamp eliminates the possibility of the log accidentally rotating during the work.

With the ball-bearing system in the tip, processing remains linear and constant without the manual intervention of an operator to free any blockages.

Mechanical coupler KLAC SYSTEM

Mechanical coupler KLAC SYSTEM HYDRAULIC KLAC SYSTEM

HYDRAULIC KLAC SYSTEM MECHANICAL COUPLER ALTERNATIK

MECHANICAL COUPLER ALTERNATIK Hydraulic and mechanical coupler KLAC +

Hydraulic and mechanical coupler KLAC + ROTATING HITCH ROTOK

ROTATING HITCH ROTOK TILTABLE HITCH TILTK

TILTABLE HITCH TILTK TILTABLE AND ROTATING HITCH

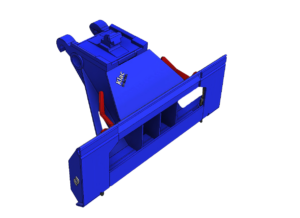

TILTABLE AND ROTATING HITCH DEMOLITION CLAMP

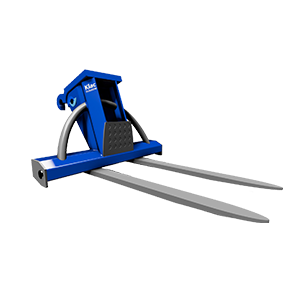

DEMOLITION CLAMP FORK PALLET LIFT

FORK PALLET LIFT SELECTION CLAMP

SELECTION CLAMP SKID ADAPTER

SKID ADAPTER HANDLING GRAPPLE

HANDLING GRAPPLE MIXING BUCKET

MIXING BUCKET NARROW BUCKET SOLO

NARROW BUCKET SOLO NARROW BUCKET Duo

NARROW BUCKET Duo NARROW BUCKET Trio

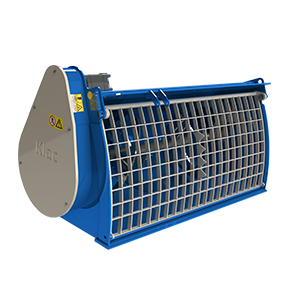

NARROW BUCKET Trio GRINDING HEAD

GRINDING HEAD HEDGE TRIMMER

HEDGE TRIMMER KLAC CITY BUCKET

KLAC CITY BUCKET HYDRAULIC PUMP

HYDRAULIC PUMP LOG SPLITTER CLAMP

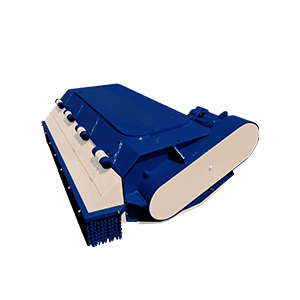

LOG SPLITTER CLAMP WOOD CLAMP

WOOD CLAMP RIPPER TOOTH

RIPPER TOOTH MULTIRIPPER BUCKET

MULTIRIPPER BUCKET KLAC MANIP

KLAC MANIP