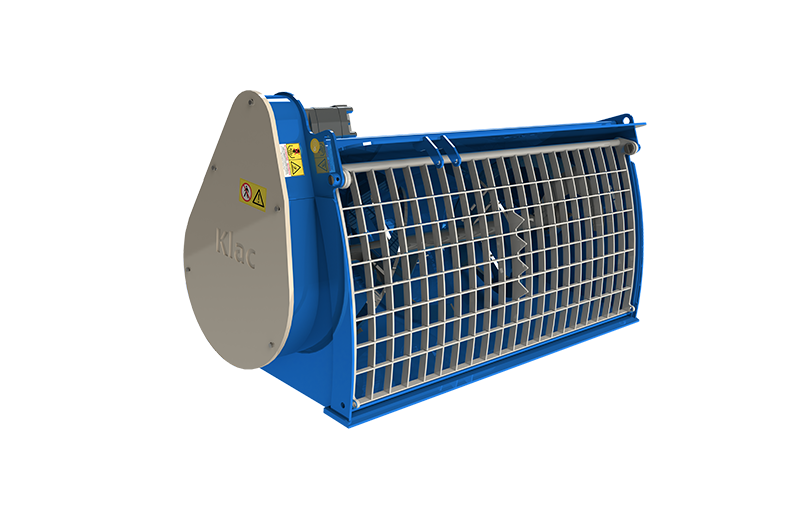

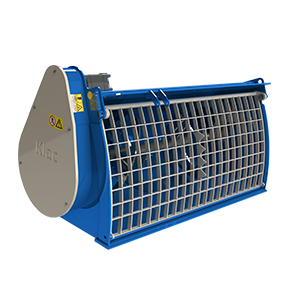

MIXING BUCKET K-MIX

A concrete solution!

Designed specifically for concrete production with mini-excavators and backhoes.

The technical solutions offer maximum efficiency and longevity.

They are equipped with a solenoid valve with electric controls and a push-button for the hydraulic opening of the outlet, flush-faced quick-connect couplers and a corrugated discharge pipe.

More information

- Manufactured using anti-wear material

- Chain drive motor

- Automatic spring tensioners fitted on the chain

- Rotation with roller bearings

- Shaft with grooved profile (Ø50/60mm)

- External grease point

- Hydraulic control of outlet opening.

MIXING BUCKET K-MIX

TECHNICAL FEATURES

Focus on

DISCHARGE

The bucket is fitted with two hooks connected to the sliding opening allowing the direction of the concrete flow to be controlled.

The pipe has a handle at the end to aid handling.

The pipe is 1.50 m long with an internal reinforcing spiral structure.

OPERATION

The machine loads sand into the bucket as normal.

When water and cement are added, the mixing screw produces concrete which is pushed towards the centre of the bucket ready to be discharged.

Simple, efficient and robust with spare parts reduced to a minimum.

THE RANGE K – MIX mixing bucket

| Weight (kg) | Width (mm) | Capacity (litres) | Total weight (kg) | Oil flow rate (L / min) | Max pressure (Bar) | |

|---|---|---|---|---|---|---|

| Model D / 1 2 – 2,8t | 180 | 1 000 | 100 | 417 | 60 | 175 |

| Model D / 1 3 – 3,5t | 250 | 1 200 | 160 | 630 | 60 | 175 |

| Model E /2 3 – 5t | 330 | 1 420 | 200 | 810 | 60 | 175 |

| Model F / 3 6 – 9t | 400 | 1 420 | 250 | 1 048 | 75 | 175 |

| Model G 9 – 12t | 420 | 1 600 | 350 | 1 274 | 75 | 175 |

| Model H 12 – 17t | 440 | 1 600 | 450 | 1 565 | 75 | 175 |

| Model I 17 – 24t | 650 | 1 950 | 600 | 2 100 | 125 | 210 |

OUR EQUIPMENT IN PICTURES

Documents

Brochure UK

SAFETY QUESTION

The bolted front grille and the grille on the slide (discharge pipe) protect the operator when the bucket is being used.

The bucket can be mounted in “normal” mode or “reversemounted” to facilitate the operator’s work.

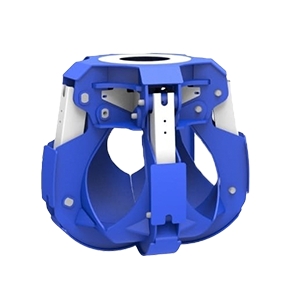

Mechanical coupler KLAC SYSTEM

Mechanical coupler KLAC SYSTEM HYDRAULIC KLAC SYSTEM

HYDRAULIC KLAC SYSTEM MECHANICAL COUPLER ALTERNATIK

MECHANICAL COUPLER ALTERNATIK Hydraulic and mechanical coupler KLAC +

Hydraulic and mechanical coupler KLAC + ROTATING HITCH ROTOK

ROTATING HITCH ROTOK TILTABLE HITCH TILTK

TILTABLE HITCH TILTK TILTABLE AND ROTATING HITCH

TILTABLE AND ROTATING HITCH DEMOLITION CLAMP

DEMOLITION CLAMP FORK PALLET LIFT

FORK PALLET LIFT SELECTION CLAMP

SELECTION CLAMP SKID ADAPTER

SKID ADAPTER HANDLING GRAPPLE

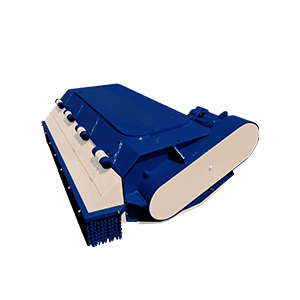

HANDLING GRAPPLE MIXING BUCKET

MIXING BUCKET NARROW BUCKET SOLO

NARROW BUCKET SOLO NARROW BUCKET Duo

NARROW BUCKET Duo NARROW BUCKET Trio

NARROW BUCKET Trio GRINDING HEAD

GRINDING HEAD HEDGE TRIMMER

HEDGE TRIMMER KLAC CITY BUCKET

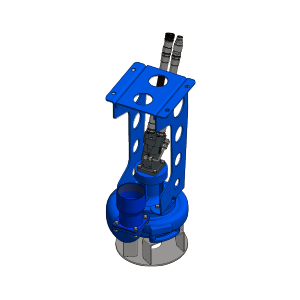

KLAC CITY BUCKET HYDRAULIC PUMP

HYDRAULIC PUMP LOG SPLITTER CLAMP

LOG SPLITTER CLAMP WOOD CLAMP

WOOD CLAMP RIPPER TOOTH

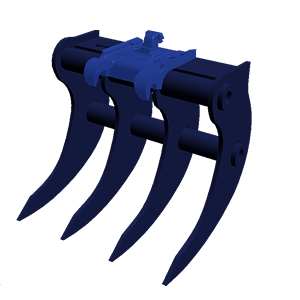

RIPPER TOOTH MULTIRIPPER BUCKET

MULTIRIPPER BUCKET KLAC MANIP

KLAC MANIP